High Pressure Vessel

Remarkably Reduce Expenses!

In this introduction, we'll delve into the features and benefits of our Commercial Size Pressure Cooker, showcasing how it streamlines the ramen-making process, while ensuring exceptional taste and quality.

Say goodbye to lengthy cooking times and hello to a world of possibilities for crafting mouthwatering ramen with ease.

Let's explore the culinary journey that awaits you with this essential kitchen tool.

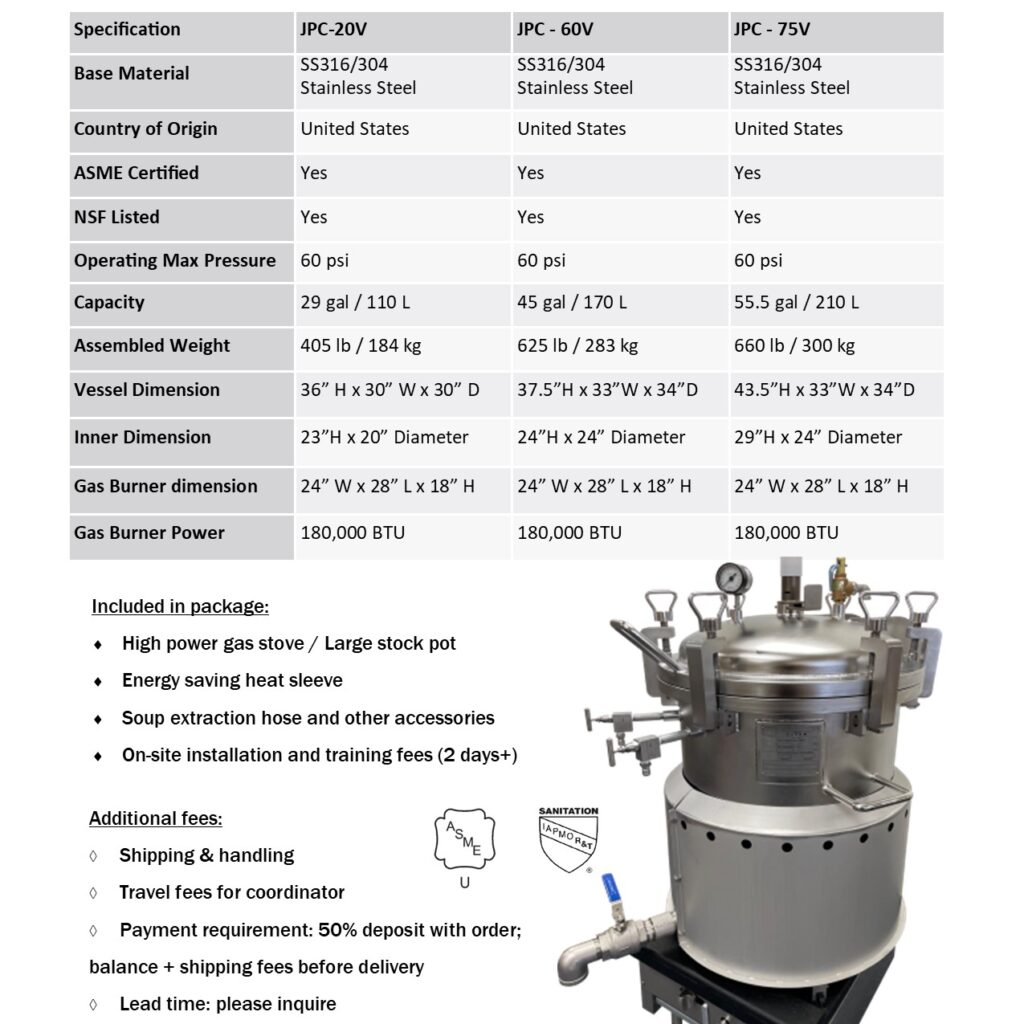

Product Lineup

3 capacities to choose from according to the size of your restaurant and kitchen!

JPC-20V

Diameter: 20.0”(500mm)

Height: 24.0”

JPC-60V

Diameter: 24.0”(600mm)

Height: 24.0”

JPC-75V

Diameter: 24.0”(600mm)

Height: 30.0”

Features

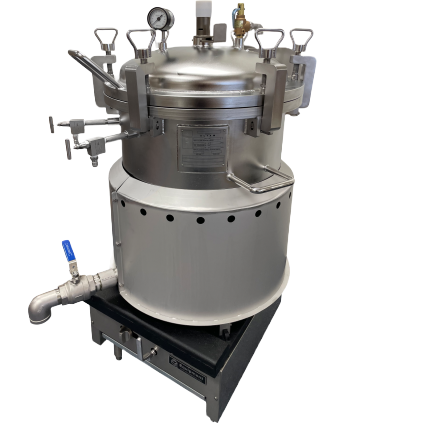

1. Safety

Reliably designed pressure cooker made with safety in mind!

- JPC High Pressure Vessel series is an ASME* certified product that incorporates a Safety exhaust system (safety cap assembly).

- Patented Safety cap assembly system and Emergency pressure relief valve are used together to eliminate the possibility of explosion due to clogging of cooking ingredients.

- SS316 stainless steel is three times stronger than aluminum and has excellent corrosion resistance.

- Electropolishing finish, unlike aluminum, does not leave lingering detergent odor after cleaning.

- Heavy-weight lid can be opened/closed safely and easily by the use of a special built-in spring.

- When delivered, our exclusive coordinator goes to the site and carefully teaches on how to use it.

2. Cooking Process

Cooking Process High skills and experience not required!

- Simple and reliable new cooking method departs from conventional ways of making soup.

- Soup can steadily be extracted in a short time.

- Eliminates annoyance of “adding water, removing scum, and filtering soup” during cooking process.

- Easy temperature control, and high reproducibility rate (over 95%) when using the same recipe.

- Quiet, no steam emitted, and no foul animal odor while cooking.

- After pressurization, heat retention allows cooking on low heat (less than 1/10 of maximum heat power).

3. Productivity

Quality soup in large amounts produced in a short time!

JPC-75V can extract approx. 400 cups of paitan soup at a time.

- Soup can be extracted in a minimum of one hour cooking time (excluding pressurization time).

- 180,000BTU jet burner and special heat-saving sleeve greatly reduce cooking time.

- Soup extraction is increased by about 10-30% when compared to traditional vessels.

- Simplifies work process and easily unifies extraction of soup.

- Demonstrates maximum advantage for multi-restaurant development.

- Hiring highly experienced workers is no longer required, making it easier to obtain employees.

4. Working environment

Improves work environment by drastically reducing cooking time!

Tonkotsu ramen soup production time, average 14 hours reduced to about 2 hours

- Shorter cooking time reduces heat emission from gas burner and rising temperature in the kitchen.

- Paitan soup can be poured from a special valve, eliminating the need for bothersome soup straining.

- Nearly all ingredients are extracted after cooking, which minimizes garbage odor and eliminates nuisance of odor to surrounding areas.

5. Cost

Simplify work process and greatly reduce costs!

- Significant reduction in cooking time dramatically reduces gas cost to about 1/6 or less for cooking soup.

- Multiple effects from reduced cooking time include sharp reduction in air conditioning cost for kitchen and restaurant.

- Eliminates procedures required for traditional cooking vessels, such as “removing soup scum, stirring, adding water, and filtering soup”, thus greatly reducing labor and water costs.

- Reduces cost of ingredients by about 30% when compared to traditional cooking vessels.

6. SDGs

Earth-friendly, zero-waste SDGs product

- After airtight high temperature pressure cooking, the bones of the ingredients are easily crushed with a special bone crusher and then palletized.

- Pallets can then be sold as healthy Calcium supplement Pet Food in vacuum packs.

Alternatively, it can be used as a fertilizer for a home vegetable garden.

7. Maintenance

Easy care and maintenance!

- Combination of bottom thickness (33mm) and Bone Basket prevents pot bottom from being scorched.

- Stainless steel scoop and Bone basket together easily remove ingredients after cooking.

- Soup discharge hose can be easily attached/detached with the stainless steel Quick Connector.

- Residual water after washing with detergent can be drained by using the special drain valve.

8. Cooking variations

Variety of cooking with one unit!

- Various ingredients such as vegetables, bones and seafood can be cooked by adjusting the pressure.

- Not limited to thick or light soup, but can also be used for boiling, steaming and fermenting. Please contact P&V Planning ramen consultants for more details.

This product uses stainless steel material with a thickness of 33mm bottom plate, 7mm side, 35mm (each) upper and lower lid flanges, and 7mm top lid. With proper care, it can be used for several decades.