Multi-Boil Auto-lift Noodle Boiler

JC Factory - Multi-Boil Auto-lift Noodle Boiler

Anyone can cook perfect noodles every time!

If your restaurant serves noodle dishes, this equipment is what you need. Expect perfect results every time when cooking ramen and all other types of noodles at a rapid speed.

Features

- Easy operation. Just put noodle in a basket. Push it down into the cooking tank and press the start button. There are six slots and they work independently with individual auto-lifts.

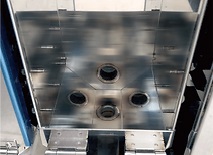

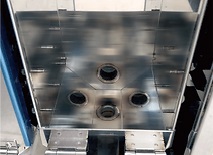

- All stainless cooking tank (SUS316)

- High temperature jet nozzles; digital timer

- Constant supply of clean hot water of up to 167F degrees (75C) at 1.4 liters per minute.

- IAPMO certified

Reliability

Multi-Boil is a reliable machine with over 10 years of improvements and modifications and over 1,000 installations in Japan, Korea, China, Singapore and USA.

Energy Efficiency

System features proprietary double heat design in which exhaust heat from the cooking tank burner is used to heat the hot water supply tank. The bottom of the cooking tank is corrugated for maximum heat transfer.

Safety

Equipped with automatic gas valve shutoff for safety when gas flames go out or when the tank is devoid of water.

Product Functions & Features

Automatic cooking using digital timer

Multi Boil is equipped with 6 cooking stations (each consists of basket, lift, jet nozzle, etc.), and each station has its independent digital timer. You can set the timer according to the desired cooking result (firm, soft, etc.). When the set time has elapsed, the basket rises out of the water and the beeper lets you know the cooking is done. This sets you free to do other things without worrying about overcooking.

Continuous clean water replenishing

Built-in hot water supply tank continuously adds hot water (about 75C) into the cooking tank keeping the cooking water clean and fresh. This supply tank is heated with exhaust heat from the main burner, and the water temperature is generally kept at around 75C depending on the ambient temperature and the rate of water being supplied to the tank.

Keep cooking water clean all the time

As fresh water is added to the cooking tank, excess water along with noodle scraps, excess flour, bubbles, etc. are drained out over the edges of the tank through the overflow skimmer keeping the cooking water clean and fresh. You can also replace the whole tank-full of water with the water in the supply tank in one maneuver without disrupting the cooking operation. However, continuous and gradual replacement of cooking water is recommended. Always use soft water to avoid malfunctions of the unit.

Digital Timer

Each basket is independently controlled by an accurate and easy-to-operate digital timer. Cooking time can be set up to 99 minutes 59 seconds.

Auto Lift

Basket automatically pops up when the timer designated cooking time has elapsed.

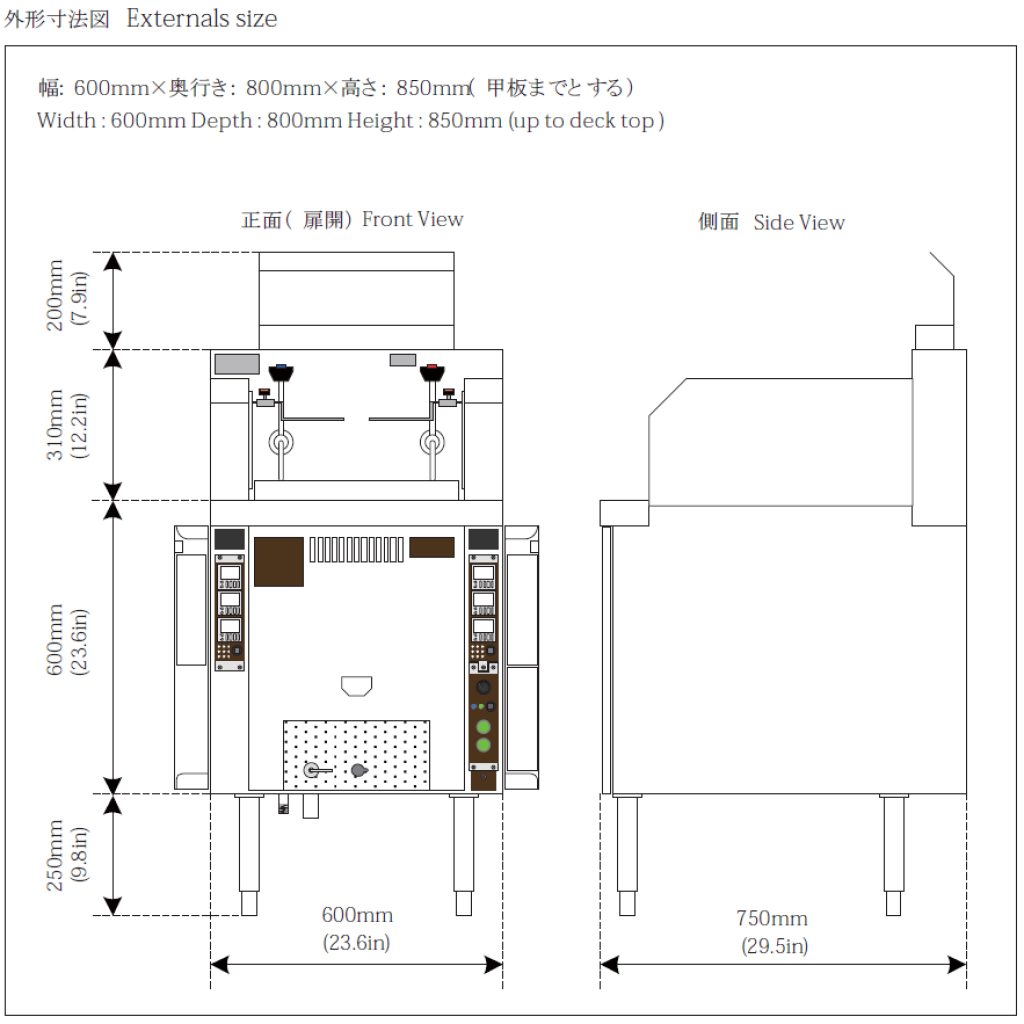

Dimensions and Specifications

Width x Depth x Height (in): 600mm(23.6in) x 750mm(29.5in) x 850mm(33.5in)

Weight (lb): 117Kg (258lb)

Installation: Exhaust Type: Indoor: Open Air

Ignition: AC120V Continuous Sparks (Direct Ignition)

Gas Connection: Natural Gas 13A :66569.3 BTU/h (19.5kW/h) / LP Gas : 66569.3 BTU/h (19.5kW/h)

Power: AC 120V (60hz)

Power Consumption: AC120V 60Hz 91W

Power Input: Single Phase 120V with Safety Ground

Gas Consumption: 1/2in Nipple Stop

Water Inlet Connection: 1/2in Nipple Stop

Drain Connection: 25A / Drain: 1″

Safety Device: Flame Out : Flame Rod / Empty Cooking : Thermostat

Basket Elevator: 6 stations (3×2)

Auto Noodle Vacuum Dryer

JC Factory

JRT-2000 Auto Noodle Vacuum Dryer

The JRT Vacuum Noodle Dryer draws out excess water clinging to noodles. You can enjoy better texture of noodles as well as maintain delicacy of flavorful soup. This ramen equipment will be the key point to upgrading your ramen to the next level.

Just put Tebo noodle basket into the noodle canister, then the contact magnet switch kicks it into power. You can easily adjust the operating time between 1 to 5 seconds with the dial timer. It is simple to use, easy to maintain, and you won’t have to deal with any more dirty sinks or floors.

JRT-2000 can help you raise the quality of your noodle business.

We recommend a combination of the Auto-lift noodle boiler & Vacuum noodle dryer.

Features

Timer

Vacuum Compartment

Tebo Canister

Vacuum Compartment

Specification

- Model : JRT-2000

- Measurement (inch / mm) : 24.0”/09.6mm[D] 15.0”/81 mm[W] 31.0”/87.4mm[H]

- Vacuum Motor : 2

- Electrical Specification : 120V / 18.0A

- Weight : 83.0 lbs / 38.0 kg